不銹鋼電纜橋架散熱計(jì)算解析:從理論到實(shí)踐的科學(xué)指南

不銹鋼電纜橋架作為電力傳輸系統(tǒng)的重要載體,其散熱性能直接影響電纜載流量與運(yùn)行。在工程設(shè)計(jì)階段,精確計(jì)算橋架散熱能力是優(yōu)化系統(tǒng)配置、預(yù)防熱失效的關(guān)鍵。本文將從熱力學(xué)原理出發(fā),系統(tǒng)解析不銹鋼電纜橋架散熱計(jì)算方法。

Stainless steel cable trays, as important carriers of power transmission systems, have a direct impact on cable current carrying capacity and operational safety due to their heat dissipation performance. In the engineering design phase, accurately calculating the heat dissipation capacity of the bridge is the key to optimizing system configuration and preventing thermal failure. This article will systematically analyze the heat dissipation calculation method of stainless steel cable trays based on thermodynamic principles.

一、散熱機(jī)理與傳熱路徑

1、 Heat dissipation mechanism and heat transfer path

不銹鋼電纜橋架散熱主要通過三種方式實(shí)現(xiàn):

The heat dissipation of stainless steel cable trays is mainly achieved through three methods:

熱傳導(dǎo):電纜產(chǎn)生的熱量經(jīng)絕緣層傳遞橋架本體,某材料實(shí)驗(yàn)室的測(cè)試數(shù)據(jù)顯示,交聯(lián)聚乙烯電纜的導(dǎo)熱系數(shù)為0.35W/(m·K),不銹鋼橋架的導(dǎo)熱系數(shù)則達(dá)15W/(m·K),形成熱傳導(dǎo)通道。

Thermal conduction: The heat generated by the cable is transferred to the bridge body through the insulation layer. Test data from a certain material laboratory shows that the thermal conductivity of cross-linked polyethylene cable is 0.35W/(m · K), while that of stainless steel bridge is 15W/(m · K), forming an efficient thermal conduction channel.

熱對(duì)流:空氣流經(jīng)橋架表面時(shí)帶走熱量,自然對(duì)流換熱系數(shù)通常為5-10W/(m2·K),強(qiáng)制通風(fēng)條件下可提升20-50W/(m2·K)。

Thermal convection: When air flows over the surface of the bridge, it carries away heat. The natural convection heat transfer coefficient is usually 5-10W/(m2 · K), which can be increased to 20-50W/(m2 · K) under forced ventilation conditions.

熱輻射:橋架表面向環(huán)境發(fā)射紅外線,某光學(xué)檢測(cè)設(shè)備的測(cè)量表明,拋光不銹鋼表面發(fā)射率約為0.15,遠(yuǎn)低于氧化表面,輻射散熱效率存在顯著差異。

Thermal radiation: The surface of the bridge emits infrared radiation into the environment. Measurements from an optical detection device show that the emissivity of polished stainless steel surfaces is about 0.15, much lower than that of oxidized surfaces, and there is a significant difference in radiation heat dissipation efficiency.

二、散熱計(jì)算核心公式

2、 Core formula for heat dissipation calculation

穩(wěn)態(tài)散熱模型

Steady-state heat dissipation model

基于能量守恒定律,橋架散熱量Q可表示為:

Based on the law of conservation of energy, the heat dissipation Q of the bridge can be expressed as:

Q = K×A×ΔT

其中,K為綜合傳熱系數(shù),A為有效散熱面積,ΔT為橋架表面與環(huán)境溫差。某電力設(shè)計(jì)院的工程手冊(cè),當(dāng)橋架間距大于100mm時(shí),K值取8-12W/(m2·K)。

Among them, K is the comprehensive heat transfer coefficient, A is the effective heat dissipation area, and Δ T is the temperature difference between the bridge surface and the environment. The engineering manual of a certain power design institute recommends that when the spacing between cable trays is greater than 100mm, the K value should be taken as 8-12W/(m2 · K).

電纜載流量修正

Correction of cable current carrying capacity

環(huán)境溫度升高會(huì)導(dǎo)致電纜載流量下降,修正公式為:

An increase in ambient temperature can lead to a decrease in cable current carrying capacity. The correction formula is:

I修正 = I基準(zhǔn)×√[(θm - θa)/(θm - θ0)]

I correction=I benchmark × √ [(θ m - θ a)/(θ m - θ 0)]

式中,θm為電纜允許溫度,θa為實(shí)際環(huán)境溫度,θ0為基準(zhǔn)溫度。某電纜廠商的測(cè)試數(shù)據(jù)顯示,當(dāng)環(huán)境溫度從25℃升40℃時(shí),相同截面積電纜的載流量下降約18%。

In the formula, θ m is the maximum allowable temperature of the cable, θ a is the actual ambient temperature, and θ 0 is the reference temperature. According to test data from a cable manufacturer, when the ambient temperature rises from 25 ℃ to 40 ℃, the current carrying capacity of cables with the same cross-sectional area decreases by about 18%.

橋架溫升計(jì)算

Calculation of Bridge Temperature Rise

對(duì)于多層電纜橋架,溫升Δτ可采用下式估算:

For multi-layer cable trays, the temperature rise Δ τ can be estimated using the following formula:

Δτ = (I2×R)/(N×A×h)

Δ τ=(I2 × R)/(N × A × h)

其中,I為電流有效值,R為電纜單位長(zhǎng)度電阻,N為電纜根數(shù),A為橋架截面積,h為表面?zhèn)鳠嵯禂?shù)。某仿真軟件的計(jì)算結(jié)果表明,當(dāng)橋架填充率超過40%時(shí),溫升速率呈指數(shù)增長(zhǎng)。

Among them, I is the effective current value, R is the resistance per unit length of the cable, N is the number of cables, A is the cross-sectional area of the bridge, and h is the surface heat transfer coefficient. The calculation results of a certain simulation software show that when the bridge filling rate exceeds 40%, the temperature rise rate increases exponentially.

三、關(guān)鍵影響因素解析

3、 Analysis of key influencing factors

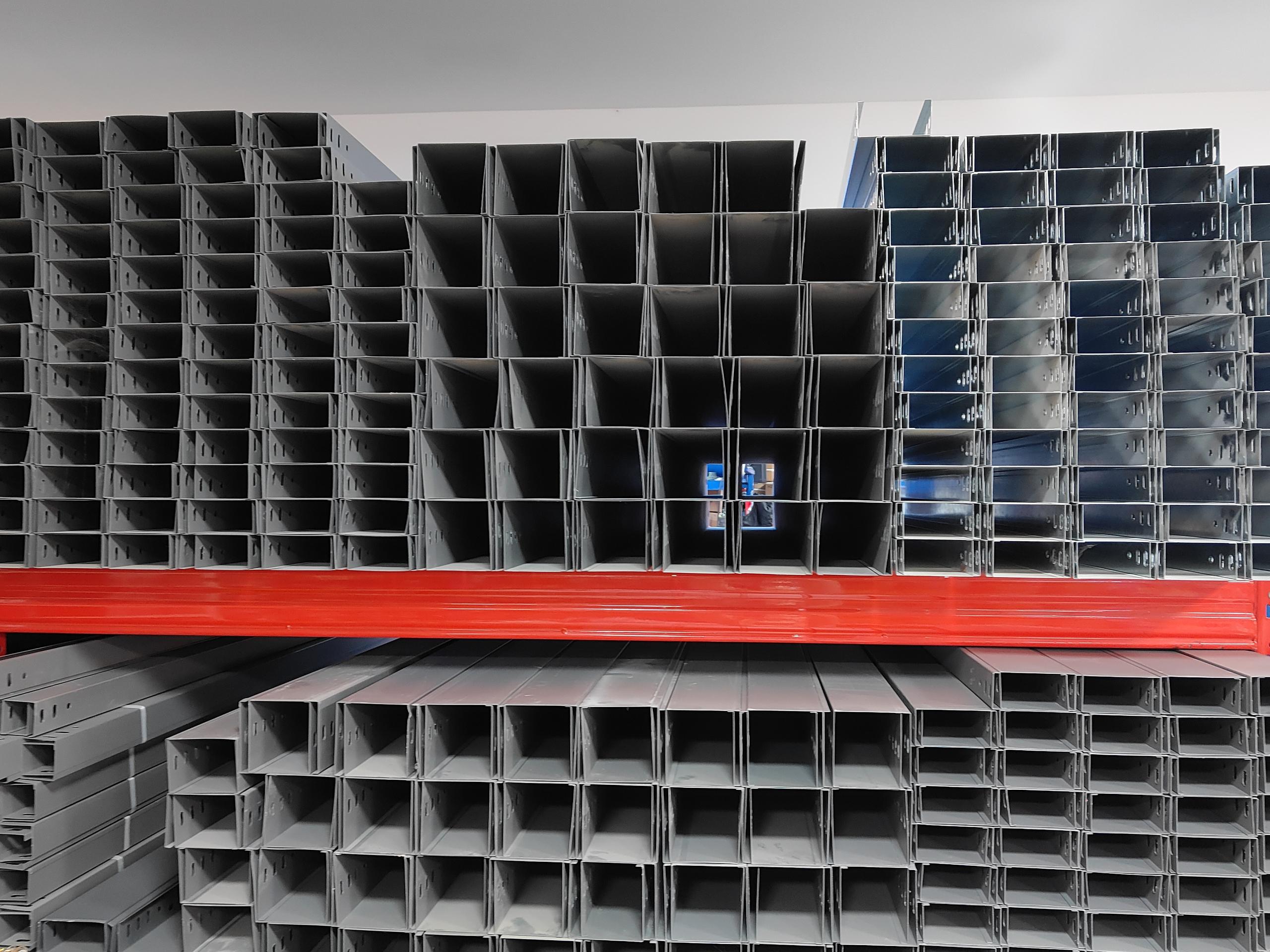

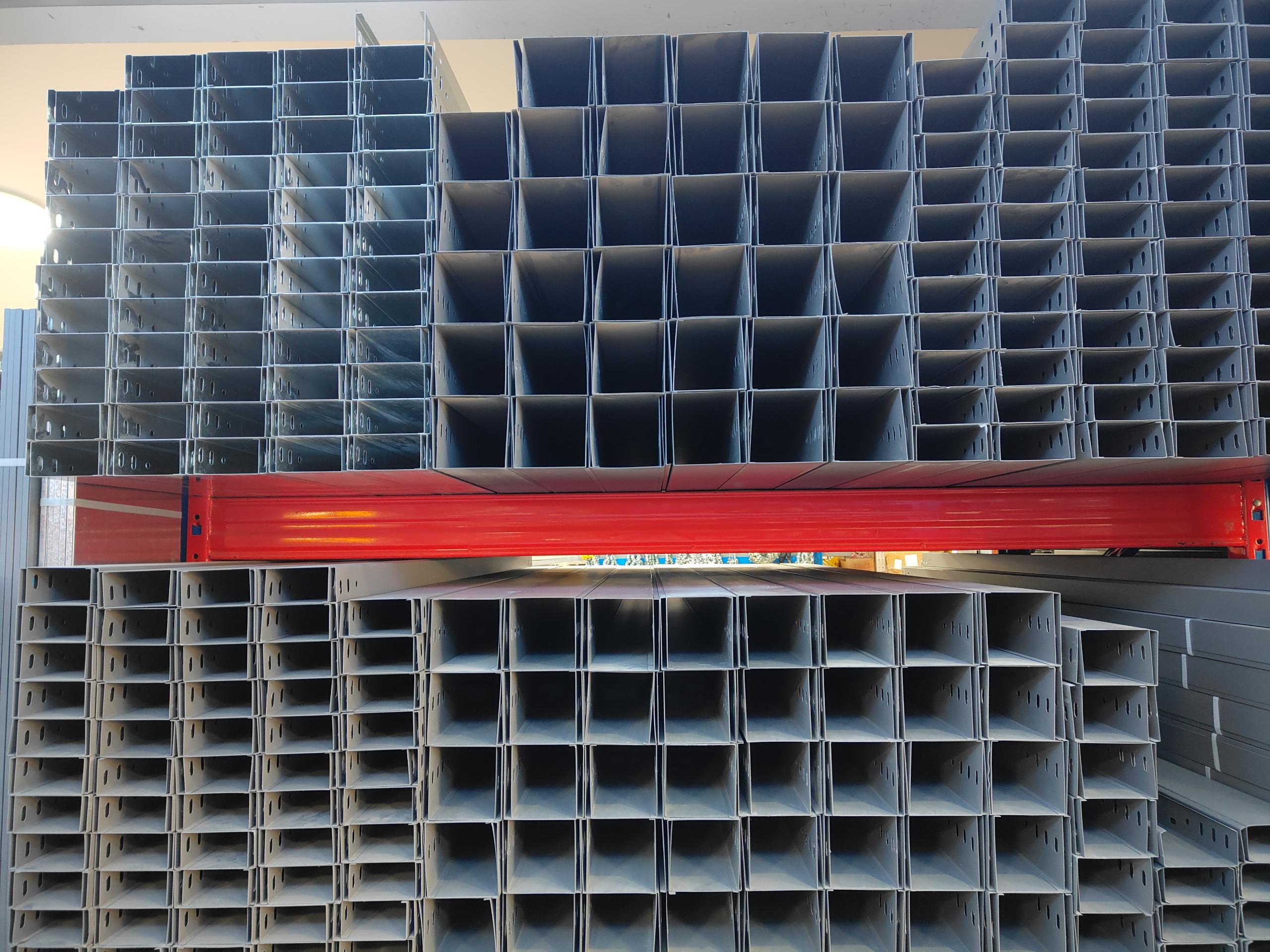

橋架結(jié)構(gòu)參數(shù)

Bridge structure parameters

截面形狀:梯級(jí)式橋架通風(fēng)性能優(yōu)于槽式橋架,某風(fēng)洞試驗(yàn)顯示,相同尺寸下梯級(jí)式橋架的自然對(duì)流換熱系數(shù)提高。

Section shape: The ventilation performance of the stepped bridge is better than that of the trough bridge. A wind tunnel test showed that the natural convection heat transfer coefficient of the stepped bridge is improved under the same size.

安裝間距:層間垂直間距每增加50mm,綜合散熱效率提升約8%。

Installation spacing: For every 50mm increase in vertical spacing between layers, the overall heat dissipation efficiency is improved by about 8%.

表面處理:噴塑處理橋架較拋光橋架表面溫度降低,因涂層發(fā)射率提高增強(qiáng)了輻射散熱。

Surface treatment: Spraying treatment reduces the surface temperature of the bridge compared to polishing, and enhances radiation heat dissipation due to the increased emissivity of the coating.

環(huán)境條件

Environmental conditions

環(huán)境溫度:IEC 60287標(biāo)準(zhǔn)規(guī)定,基準(zhǔn)環(huán)境溫度取40℃,每升高1℃,電纜載流量需修正。

Environmental temperature: According to the IEC 60287 standard, the reference environmental temperature is set at 40 ℃. For every 1 ℃ increase, the cable current carrying capacity needs to be adjusted.

海拔高度:海拔每升高1000m,空氣密度下降,對(duì)流換熱系數(shù)降低約10%。

Altitude: For every 1000m increase in altitude, the air density decreases and the convective heat transfer coefficient decreases by about 10%.

日照強(qiáng)度:露天橋架需考慮太陽輻射,某氣象站的監(jiān)測(cè)數(shù)據(jù)顯示,夏季正午太陽輻射強(qiáng)度可達(dá)1000W/m2。

Sunshine intensity: Outdoor cable trays need to consider solar radiation. Monitoring data from a certain meteorological station shows that the solar radiation intensity at noon in summer can reach 1000W/m2.

電纜配置方式

Cable configuration method

填充率:橋架填充率應(yīng)控制在30%-50%,某火災(zāi)實(shí)驗(yàn)室的試驗(yàn)表明,填充率超過60%時(shí),緊急情況下的熱釋放速率增加。

Filling rate: The filling rate of the bridge should be controlled between 30% and 50%. A test conducted in a fire laboratory showed that when the filling rate exceeds 60%, the heat release rate in emergency situations increases.

排列方式:三角形排列較水平排列散熱效率高,因形成自然煙囪效應(yīng)。

Arrangement method: Triangular arrangement has higher heat dissipation efficiency than horizontal arrangement due to the formation of natural chimney effect.

不銹鋼電纜橋架散熱計(jì)算是涉及多物理場(chǎng)耦合的復(fù)雜工程問題。通過建立精確的熱平衡模型,綜合考慮結(jié)構(gòu)參數(shù)、環(huán)境條件與電纜配置,可實(shí)現(xiàn)散熱性能的量化評(píng)估。在實(shí)際工程中,應(yīng)優(yōu)先采用仿真工具進(jìn)行方案比選,結(jié)合智能監(jiān)測(cè)技術(shù)構(gòu)建預(yù)防性維護(hù)體系。隨著導(dǎo)熱材料與數(shù)字孿生技術(shù)的發(fā)展,橋架散熱設(shè)計(jì)正朝著更精準(zhǔn)、更智能的方向演進(jìn),這對(duì)保障電力系統(tǒng)運(yùn)行具有重要意義。

The heat dissipation calculation of stainless steel cable trays is a complex engineering problem involving the coupling of multiple physical fields. By establishing an accurate thermal balance model, taking into account structural parameters, environmental conditions, and cable configuration, a quantitative evaluation of heat dissipation performance can be achieved. In practical engineering, simulation tools should be prioritized for scheme comparison, combined with intelligent monitoring technology to construct a preventive maintenance system. With the development of thermal conductive materials and digital twin technology, bridge heat dissipation design is evolving towards more precise and intelligent directions, which is of great significance for ensuring the safe operation of power systems.

本文由山東電纜橋架友情奉獻(xiàn).更多有關(guān)的知識(shí)請(qǐng)點(diǎn)擊 http://www.zkhtkj.cn 真誠的態(tài)度.為您提供為的服務(wù).更多有關(guān)的知識(shí)我們將會(huì)陸續(xù)向大家奉獻(xiàn).敬請(qǐng)期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://www.zkhtkj.cn Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.山東電纜橋架

下一篇:電纜橋架防火性能判斷指南

相關(guān)文章 / Recommended news

- 濟(jì)南廠房福音!大跨距橋架破解3大痛點(diǎn),加強(qiáng)筋加,安裝省一半錢

- 山東工程人警惕!橋架敷線踩這坑必返工,監(jiān)理當(dāng)場(chǎng)叫停,國(guó)標(biāo)早有明確規(guī)定

- 濟(jì)南人避坑!橋架≠線槽,90%工程人都搞混,一字之差差千里

- 避坑指南!山東電纜橋架規(guī)格別瞎選,偏大浪費(fèi)偏小隱患大,國(guó)標(biāo)早就定好了

- 濟(jì)南人必看!鋁合金電纜橋架選對(duì)厚度,耐用又省心,90%的人選錯(cuò)踩坑

- 山東人必看!電纜橋架不是“鐵架子”,藏著建筑用電的密碼,90%的人都不懂

- 800kg/m抗壓!濟(jì)南電纜橋架,破解3大工程痛點(diǎn),工期省30%

- 3種類型+98%散熱!山東電纜橋架,選對(duì)不踩坑,布線效率翻倍

- 2類核心支架!濟(jì)南電纜橋架,抗震承重雙達(dá)標(biāo)

- 別再混淆!山東電纜橋架vs線槽,6大核心區(qū)別一文分清

陽極氧化鋁合金橋架

陽極氧化鋁合金橋架 托盤式電纜橋架

托盤式電纜橋架 梯式電纜橋架

梯式電纜橋架 梯式不銹鋼電纜橋架

梯式不銹鋼電纜橋架 深灰色金屬防火電纜橋架

深灰色金屬防火電纜橋架