怎么保證山東電纜橋架安裝的穩固?

要保證山東電纜橋架安裝的穩固,可從以下幾個方面著手:

To ensure the stable installation of cable trays in Shandong, the following aspects can be taken into account:

1.合理設計與規劃

1. Reasonable design and planning

· 路徑規劃:根據停車場的布局和電纜走向,合理規劃橋架路徑,盡量減少彎折和交叉,避免橋架在車輛頻繁行駛區域或易受外力沖擊的位置。

·Path planning: Based on the layout of the parking lot and cable routing, plan the cable tray path reasonably, minimize bends and intersections, and avoid cable trays in areas where vehicles frequently travel or are easily impacted by external forces.

· 承載能力計算:根據停車場內電纜的數量、規格和重量,精確計算橋架的承載能力,選擇合適規格和材質的橋架,確保其能夠承受電纜的重量以及可能受到的外力。

·Load bearing capacity calculation: Based on the number, specifications, and weight of cables in the parking lot, accurately calculate the load bearing capacity of the cable tray, select the appropriate specifications and materials of the cable tray, and ensure that it can withstand the weight of the cables and possible external forces.

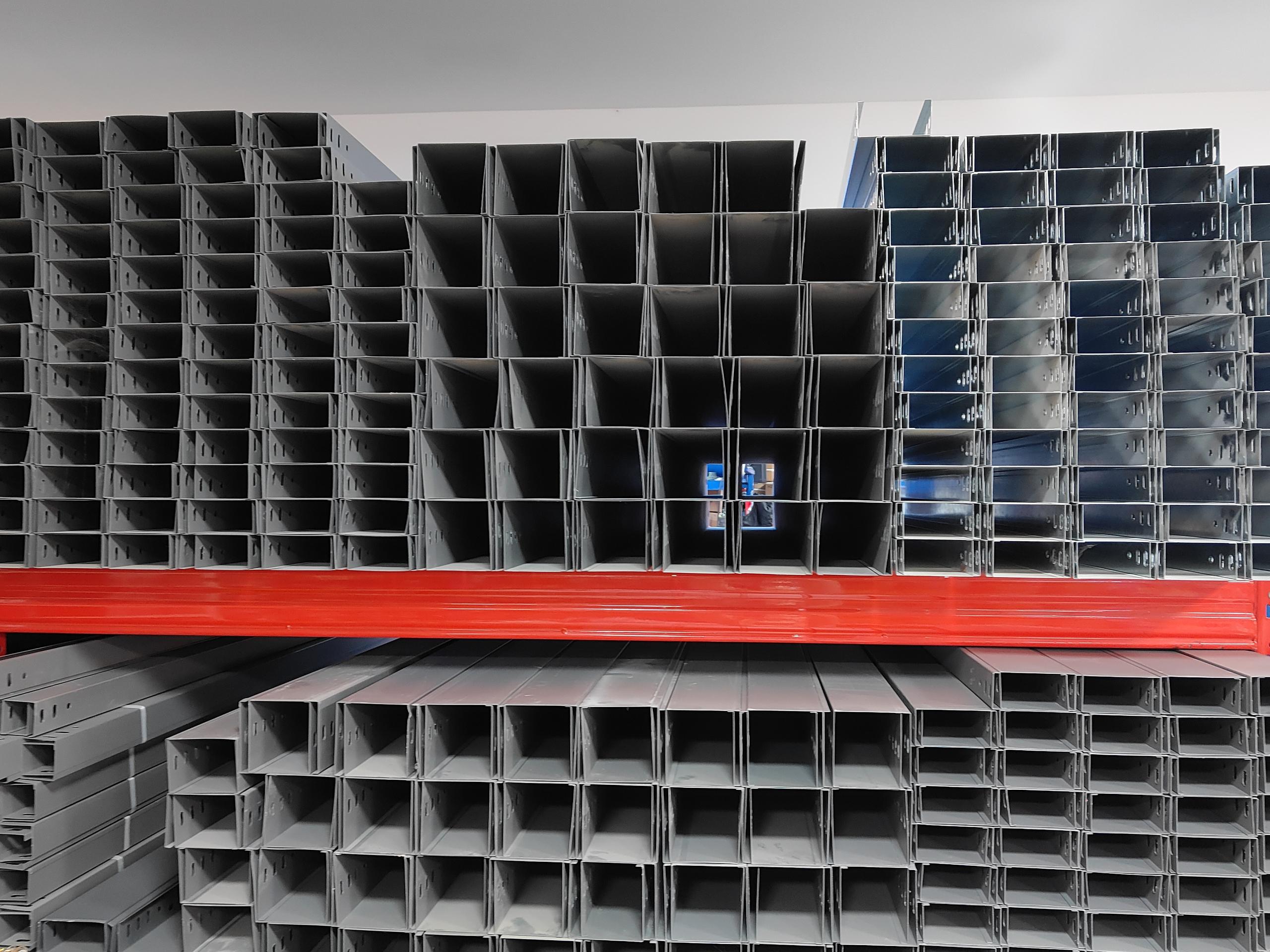

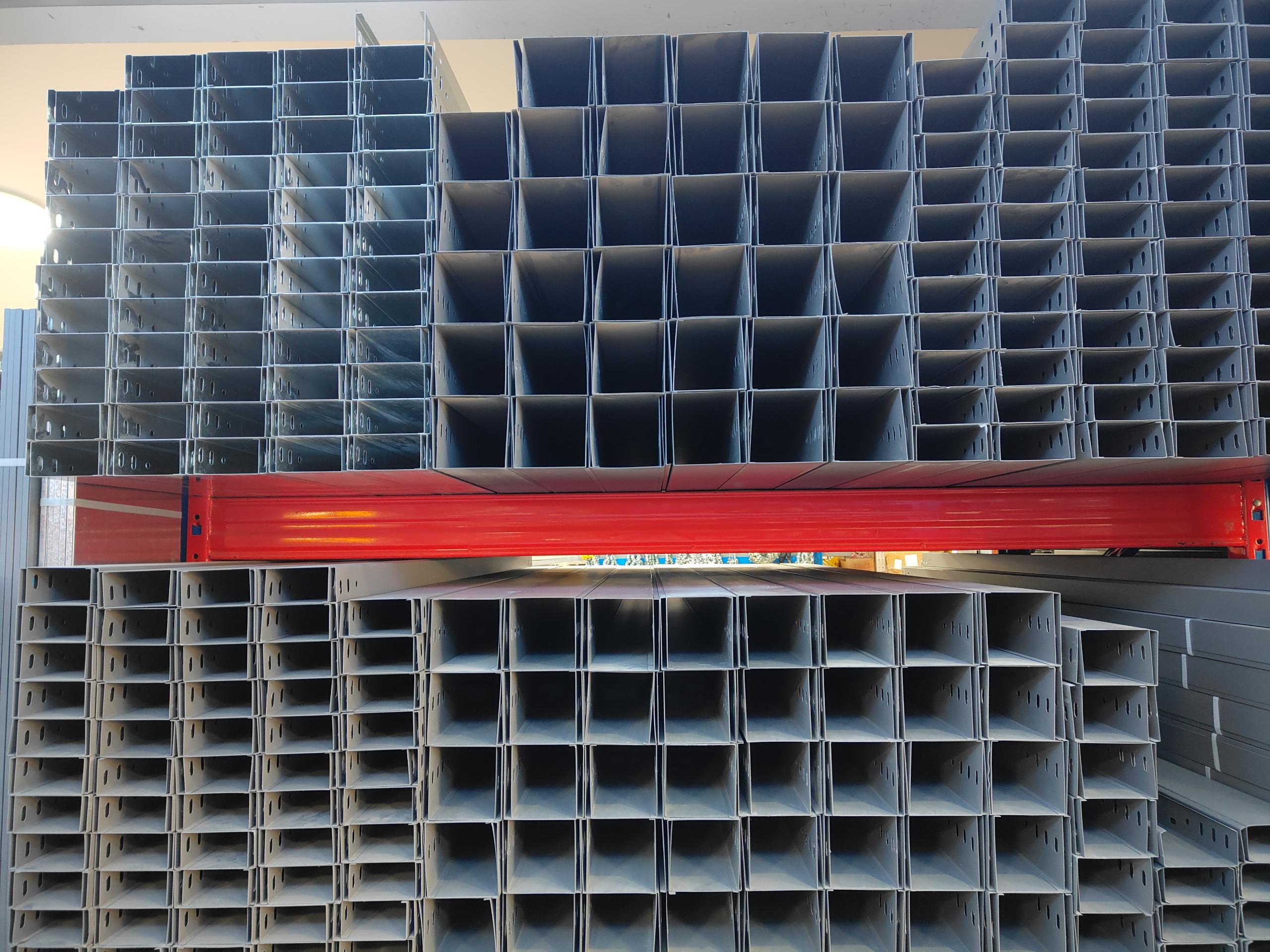

2.選擇材料

2. Choose high-quality materials

· 橋架材質:在停車場這種可能有腐蝕性物質(如汽車尾氣、雨水等)的環境中,優先選擇耐腐蝕性能好的材料,如不銹鋼、鋁合金或經過熱浸鍍鋅處理的鋼材。

·Bridge material: In environments such as parking lots that may contain corrosive substances (such as car exhaust, rainwater, etc.), it is preferred to choose materials with good corrosion resistance, such as stainless steel, aluminum alloy, or steel that has been hot-dip galvanized.

· 配件質量:選用質量可靠的橋架配件,如連接板、螺栓、螺母等,確保配件的強度和耐久性,避免因配件質量問題導致橋架松動或損壞。

·Accessory quality: Choose reliable bridge accessories such as connecting plates, bolts, nuts, etc., to ensure the strength and durability of the accessories and avoid loosening or damage to the bridge due to accessory quality issues.

3.規范安裝施工

3. Standardize installation and construction

· 支吊架安裝:

·Installation of supports and hangers:

· 間距合理:水平敷設時,支吊架間距一般為1.5-3m;垂直敷設時,固定點間距不宜大于2m。在橋架的轉彎處、分支處、接頭處以及與設備連接處等位置,應增設支吊架進行加固。

·Reasonable spacing: When laid horizontally, the spacing between supports and hangers is generally 1.5-3m; when laid vertically, the spacing between fixed points should not exceed 2m. At the turning points, branches, joints, and equipment connections of the bridge, supports and hangers should be added for reinforcement.

· 固定牢固:支吊架應牢固固定在建筑物的結構上,如梁、柱、墻壁等,不得固定在工藝管道、通風管道或其他不穩定的設備上。使用膨脹螺栓、焊接等方式固定時,要確保連接牢固,螺栓應擰緊,焊接質量符合要求。

·Fixed firmly: The support and hanger should be firmly fixed to the structure of the building, such as beams, columns, walls, etc., and should not be fixed to process pipelines, ventilation ducts, or other unstable equipment. When using expansion bolts, welding, and other methods to fix, it is necessary to ensure a firm connection, tighten the bolts, and ensure that the welding quality meets the requirements.

· 橋架連接:橋架之間的連接應緊密、牢固,連接板的螺栓應均勻擰緊,螺母應位于橋架外側。對于非鍍鋅橋架,連接板兩端需用不小于4mm?的銅芯線進行跨接,以保證橋架系統的電氣連通性。

·Bridge connection: The connection between bridge frames should be tight and firm, and the bolts of the connecting plate should be evenly tightened. The nuts should be located on the outside of the bridge frame. For non galvanized cable trays, the two ends of the connecting plate need to be bridged with copper core wires of not less than 4mm to ensure the electrical connectivity of the cable tray system.

· 接地處理:金屬橋架應可靠接地,接地電阻應符合要求。橋架全長不少于2處與接地干線可靠連接,起始端和終端必須與建筑接地裝置連接。接地連接點應采用專用的接地螺栓或接地夾,確保接地良好。

·Grounding treatment: The metal bridge should be reliably grounded, and the grounding resistance should meet the requirements. The total length of the bridge shall be reliably connected to the grounding main line at no less than 2 points, and the starting and ending ends must be connected to the building grounding device. The grounding connection point should use dedicated grounding bolts or clamps to ensure good grounding.

4.安裝后的檢查與維護

4. Inspection and maintenance after installation

· 安裝驗收:安裝完成后,對橋架進行檢查,包括橋架的水平度、垂直度、支吊架間距、連接緊固程度、接地情況等,確保各項指標符合規范要求。

·Installation acceptance: After installation is completed, a comprehensive inspection of the bridge frame is carried out, including the levelness, verticality, spacing between supports and hangers, degree of connection tightness, grounding condition, etc., to ensure that all indicators meet the specifications.

· 定期巡檢:在停車場投入使用后,定期對橋架進行巡檢,檢查橋架是否有變形、松動、腐蝕等情況,及時發現并處理潛在的問題。

·Regular inspection: After the parking lot is put into use, the bridge frame should be inspected regularly to check for deformation, looseness, corrosion, and other issues. Potential problems should be promptly identified and addressed.

· 負荷管理:嚴格控制橋架內電纜的敷設數量和重量,避免超載運行。如果需要增加電纜,應重新評估橋架的承載能力,并采取相應的加固措施。

·Load management: Strictly control the number and weight of cables laid in the cable tray to avoid overloading operation. If additional cables are required, the load-bearing capacity of the cable tray should be reassessed and corresponding reinforcement measures should be taken.

本文由 山東電纜橋架 友情奉獻.更多有關的知識請點擊 http://www.zkhtkj.cn/ 真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from Shandong Cable Bridge For more related knowledge, please click http://www.zkhtkj.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

下一篇:濟南電纜橋架總是搖晃一定要重視

相關文章 / Recommended news

陽極氧化鋁合金橋架

陽極氧化鋁合金橋架 托盤式電纜橋架

托盤式電纜橋架 梯式電纜橋架

梯式電纜橋架 梯式不銹鋼電纜橋架

梯式不銹鋼電纜橋架 深灰色金屬防火電纜橋架

深灰色金屬防火電纜橋架