濟南電纜橋架安裝施工要求及規范

電纜橋架在我國的應用只有十多年,在歐美發達也不過是幾十年。在一個機房項目中,比起造價昂貴、高科技的硬件和軟件,橋架顯的很不起眼,也很少為人關注,但它卻也是整個布線工程中不可缺少的部分。那么在施工中電纜橋架安裝施工要求及規范怎么樣?

The application of cable trays in China has only been more than ten years, and in developed countries in Europe and America, it is only a few decades. In a computer room project, compared to expensive and high-tech hardware and software, cable trays may appear inconspicuous and receive little attention, but they are still an indispensable part of the entire cabling project. So what are the requirements and standards for the installation of cable trays during construction?

1 一般規定 1.1本章適用于電壓為10KV及以下新建擴建的一般工業與民用建筑電纜、橋架安裝和橋架內電纜敷設

1 General Provisions 1.1 This chapter applies to the installation of cables, cable trays, and cable laying inside cable trays for newly constructed and expanded general industrial and civil buildings with a voltage of 10KV or below

1.2電纜橋架安裝和橋架內電纜敷設,應按已批準的設計文件施工。

1.2 The installation of cable trays and the laying of cables inside the trays shall be carried out in accordance with the approved design documents.

1.3由支、吊、托架支撐的托盤(槽)或梯架直線段、彎通非直線段組合而成,敷設電纜具有連續性的剛性結構系統,為電纜橋架。見圖1.3

1.3 A rigid structural system consisting of trays (troughs) or ladder straight sections and curved non straight sections supported by supports, hangers, and brackets, with continuous cable laying, is called a cable tray. Refer to Figure 1.3

1.4 金屬電纜橋架及其支架和引入或引出的金屬電纜導管必須接地(PE)或接零(PEN)可靠,且必須符合下列規定:

1.4 Metal cable trays and their supports, as well as metal cable conduits introduced or led out, must be reliably grounded (PE) or grounded (PEN), and must comply with the following regulations:

1.4.1金屬電纜橋架及支架全長應不少于2處與接地(PE)或接零(PEN)干線相連接;

1.4.1 The total length of metal cable trays and supports should be connected to the grounding (PE) or neutral (PEN) main line at no less than 2 points;

1.4.2非鍍鋅電纜橋架間連接板的兩端跨接線銅芯接地線,接地線小允許截面積不小于4mm2;

1.4.2 Copper core grounding wire for the two ends of the connecting plate between non galvanized cable trays, with a minimum allowable cross-sectional area of not less than 4mm2 for the grounding wire;

1.4.3鍍鋅電纜橋架間連接板的兩端不跨接接地線,但連接板兩端不少于2個有防松螺帽或防松墊圈的連接固定螺栓。

1.4.3 The two ends of the connecting plate between galvanized cable trays shall not be connected to the grounding wire, but there shall be no less than 2 connection fixing bolts with anti loosening nuts or anti loosening washers at both ends of the connecting plate.

1.4.5電纜敷設嚴禁有絞擰、鎧裝壓扁、護層斷裂和表面嚴重劃傷等缺陷。

1.4.5 Cable laying must strictly prohibit defects such as twisting, flattening of armor, breakage of protective layer, and severe surface scratches.

1.4.6電纜橋架處如有防火要求的場所,應采取防火隔離措施。

If there are fire prevention requirements at the cable tray location, fire isolation measures should be taken.

2 施工準備

2. Construction preparation

2.1 技術準備:

2.1 Technical Preparation:

2.1.1按照已批準的施工組織設計(施工方案)進行技術、交底。

2.1.1 Conduct technical and safety briefings in accordance with the approved construction organization design (construction plan).

2.1.2 施工執行工藝標準、圖集、規范齊全。

2.1.2 The construction execution process standards, drawings, and specifications are complete.

2.1.3電纜橋架敷設前,應檢查橋架敷設有無與其他設備、管線交叉或重疊無法施工的地方,施工前應與各工種、監理或建設單位及設計單位協商好,并作好記錄,以保證施工順利進行。

Before laying cable trays, it is necessary to check whether there are any areas where the tray crosses or overlaps with other equipment or pipelines that cannot be constructed. Prior to construction, it is necessary to consult with various trades, supervisors, construction units, and design units, and make records to ensure smooth construction.

2.1.4根據施工圖或施工所用電纜應作好電纜牽引力的計算。

2.1.4 According to the construction drawings or the cables used for construction, the calculation of cable traction force should be carried out.

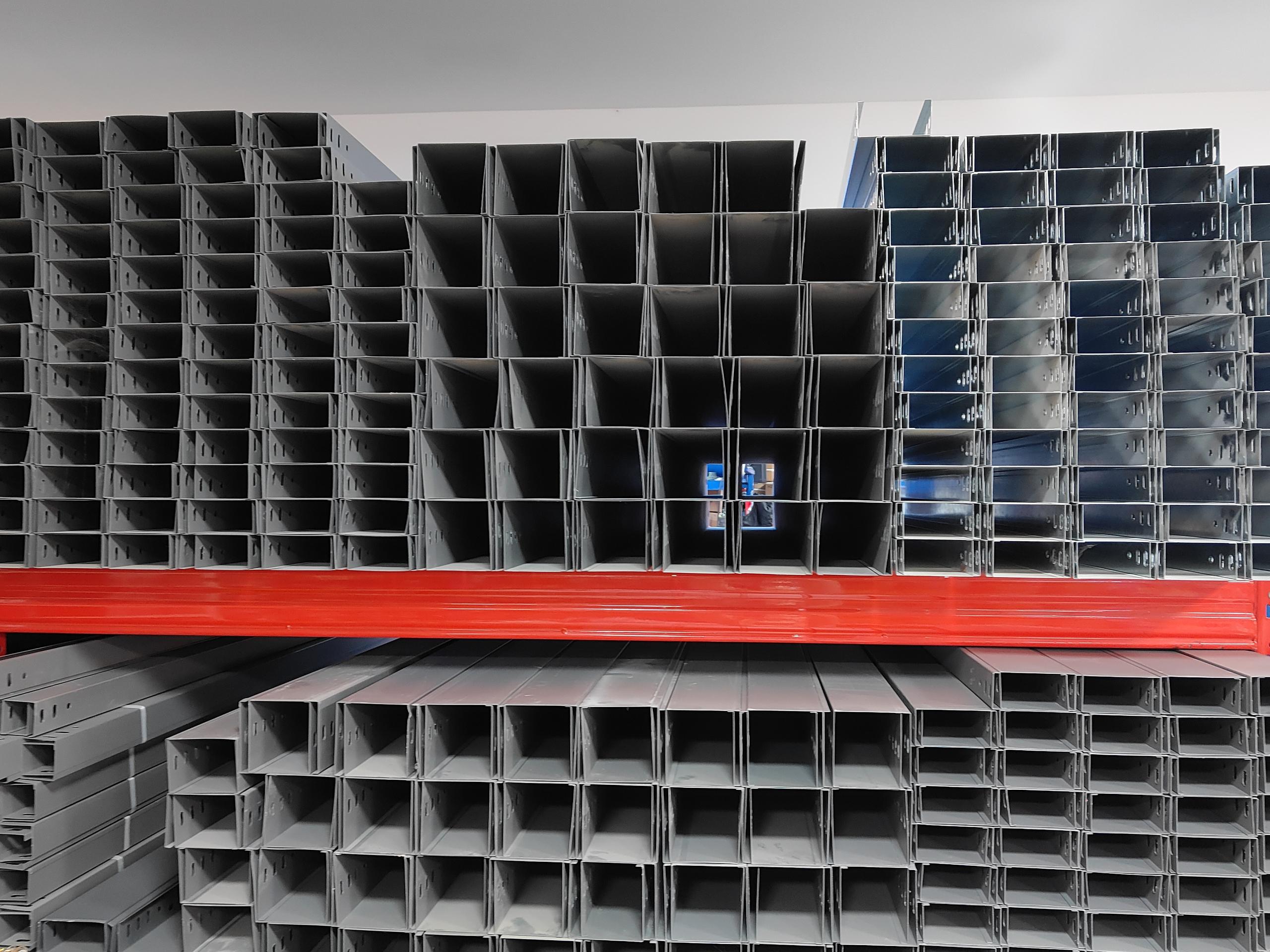

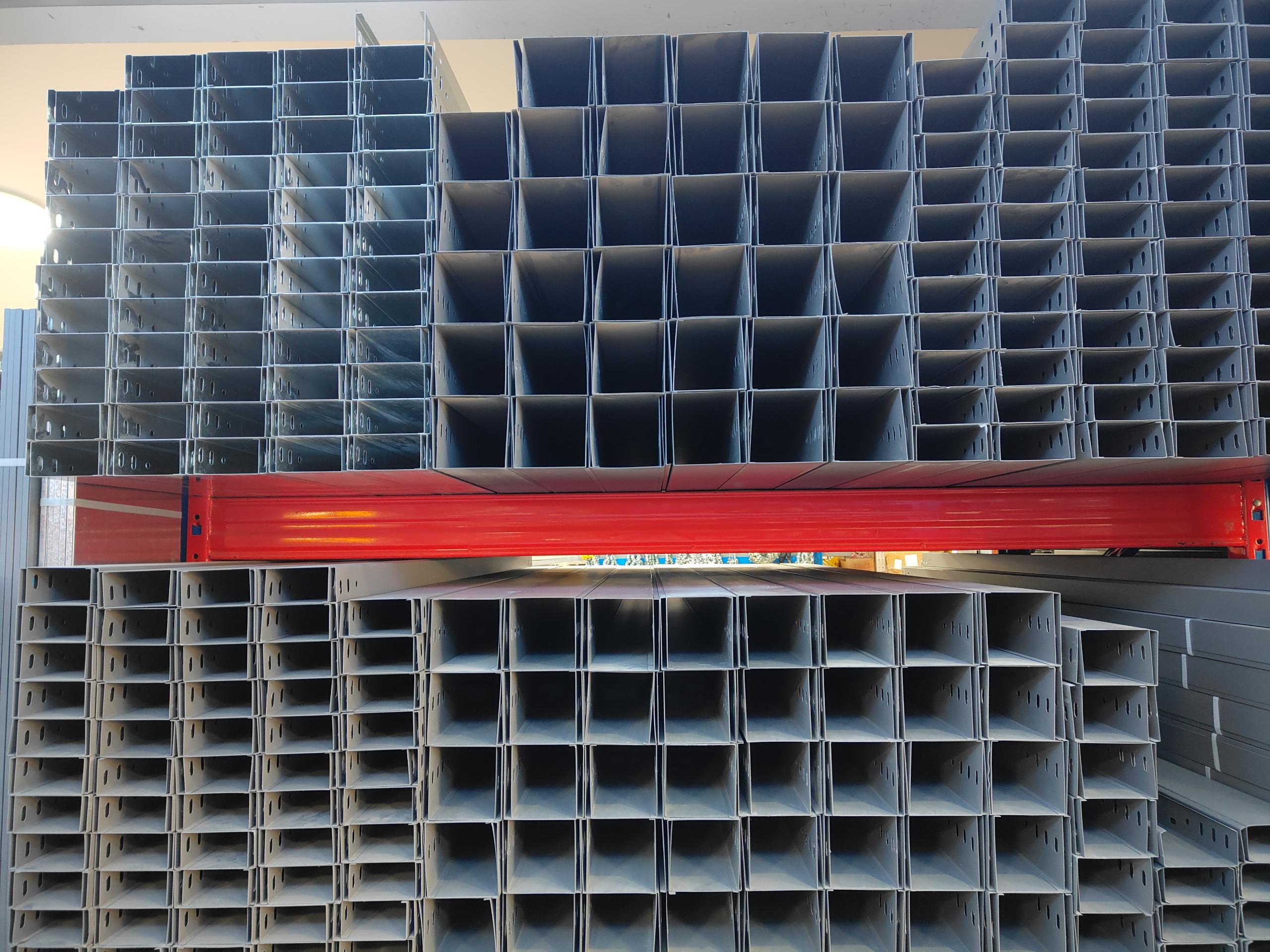

1.電纜橋架規格及型號必須符合設計要求,附件齊全;橋架與配件、附件和緊固件各種型鋼均應采用鍍鋅標準件。

1. The specifications and models of cable trays must meet the design requirements, and all accessories must be complete; All types of steel for cable trays, accessories, attachments, and fasteners should use galvanized standard parts.

2.各種規格電纜橋架的直線段、彎通、橋架附件及支、吊架立柱及型鋼等有產品合格證,橋架內外應光滑平整,無棱刺,不應有扭曲翹邊等變形現象。

2. The straight sections, bends, accessories, supports, hangers, columns, and steel sections of various specifications of cable trays should have product certification. The inside and outside of the tray should be smooth and flat, without edges or burrs, and there should be no distortion or warping.

3.橋架訂貨或制作應按設計要求進行,不應有誤,應反復校核以免造成浪費。

3. The ordering or production of cable trays should be carried out according to the design requirements, without errors, and should be repeatedly checked to avoid waste.

4.橋架安裝選擇需屏蔽電氣干擾的電纜回路,有腐蝕的場所、易燃粉塵場所,應選用無蓋無孔封閉型托盤,當需要因地制宜的場所,宜選用組裝式托盤或有孔托盤及梯架;在容易積灰和其它需遮蓋的環境或戶外場所,宜帶有蓋板。低壓電力電纜與控制電纜共用同一托盤或梯架時,應選用中間有隔板的托盤或梯架;在托盤、梯架分支、引上、引下處應設適當的彎通;因受空間條件限制不便裝設彎通或有特殊要求時,可選用軟連接板,鉸接板;伸縮縫應設置伸縮板;連接兩段不同寬度或高度的托盤、梯架可配置變寬或變高板。但在施工中,支、吊架和橋架的選擇應依設計或工程布置條件選擇。

4. When installing cable trays, cable circuits that need to be shielded from electrical interference should be selected. In places with corrosion and flammable dust, uncovered and non perforated enclosed trays should be used. When suitable for local conditions, assembled trays or perforated trays and ladders should be selected; In environments or outdoor places that are prone to dust accumulation and require cover, it is advisable to have a cover plate. When low-voltage power cables and control cables share the same tray or ladder, a tray or ladder with a partition in the middle should be selected; Appropriate bends should be installed at the branching, leading up, and leading down points of pallets and ladders; When it is not convenient to install bends due to space constraints or there are special requirements, soft connecting plates and hinged plates can be used; Expansion joints should be equipped with expansion plates; Connecting two trays or ladders of different widths or heights can be configured with variable width or height boards. However, during construction, the selection of supports, hangers, and cable trays should be based on the design or engineering layout conditions.

5.托盤、梯架的寬和高度,應按下列要求選擇:

5. The width and height of pallets and ladders should be selected according to the following requirements:

(1)電纜在橋架內的填充率,電力電纜不應大于40%;控制電纜不應大于50%。并應留有一定的備用空位,以便今后為增添電纜用;

(1) The filling rate of cables in cable trays should not exceed 40% for power cables; The control cable should not exceed 50%. And there should be some spare space left for future cable additions;

(2)所選托盤、橋架規格的承載能力應滿足規定。其工作均布荷載不應大于所選托盤、梯架荷載等級的額定均布荷載;

(2) The bearing capacity of the selected tray and bridge specifications should meet the requirements. The uniformly distributed load of its work should not exceed the rated uniformly distributed load of the selected pallet and ladder load level;

(3)工作均布荷載下的相對撓度不宜大于1/200。

(3) The relative deflection under uniformly distributed load should not exceed 1/200.

托盤、梯架直線段,可按單件標準長度選擇。單件標準長度一般規定為2、3、4、6m。托盤、梯架的寬度與高度常用規格尺寸系列如表2.4-1

Tray and ladder straight sections can be selected according to the standard length of a single piece. The standard length of a single piece is generally specified as 2, 3, 4, and 6 meters. The commonly used specifications and dimension series for the width and height of pallets and ladders are shown in Table 2.4-1

注:符號△表示常用規格。

Note: The symbol △ represents commonly used specifications.

各類彎通及附件規格,應適合工程布置條件,并與托盤、梯架配套。

All types of bends and accessory specifications should be suitable for the engineering layout conditions and matched with pallets and ladders.

支、吊架規格選擇,應按托盤、梯架規格層數、跨距等條件配置,并應滿足荷載的要求。

The selection of support and hanger specifications should be based on the number of layers, span, and other conditions of the pallet and ladder, and should meet the requirements of the load.

鋼制橋架的表面處理方式,應按工程環境條件、重要性、耐久性和技術經濟性等因素進行選擇。一般情況宜按表2.4-2選擇適用工程環境條件的防腐處理方式。當采用表中“T”類防腐方式為鍍鋅鎳合金、高純化等其它防腐處理的橋架,應按規定試驗驗證,并應具有明確的技術質量指標及檢測方式。

The surface treatment method for steel cable trays should be selected based on factors such as engineering environmental conditions, importance, durability, and technical economy. Generally, it is advisable to choose the anti-corrosion treatment method that is suitable for the engineering environmental conditions according to Table 2.4-2. When using the "T" anti-corrosion method in the table, such as galvanized nickel alloy, high-purity or other anti-corrosion treatments, the bridge should be tested and verified according to regulations, and should have clear technical quality indicators and testing methods.

注:符號“○”表示防腐類別。

Note: The symbol "○" indicates the recommended anti-corrosion category.

6.橋架的外觀檢查

6. Appearance inspection of bridge frame

橋架產品包裝箱內應有裝箱清單、產品合格證及出廠檢驗報告。托盤、梯架板材厚度應滿足表2.6的規定。表面防腐層材料應符合現行有關標準的規定。

The packaging box for bridge products should include a packing list, product certification, and factory inspection report. The thickness of pallets and ladder boards should meet the requirements of Table 2.6. The surface anti-corrosion coating material should comply with the relevant national standards currently in effect.

熱浸鍍鋅的托盤、橋架鍍層表面應均勻,無毛刺、過燒、掛灰、傷痕、局部未鍍鋅(直徑2mm以上)等缺陷,不得有影響安裝的鋅瘤。螺紋的鍍層應光滑,螺栓連接件應能擰入。

The surface of hot-dip galvanized trays and cable trays should be uniform, without defects such as burrs, overburning, hanging dust, scars, and partial non galvanizing (diameter of 2mm or more), and there should be no zinc nodules that affect installation. The coating of the thread should be smooth, and the bolt connection should be able to be screwed in.

電鍍鋅的鋅層表面應光滑均勻,致密。不得有起皮、氣泡、花斑、局部未鍍、劃傷等缺陷。

The surface of the zinc layer of electroplated zinc should be smooth, uniform, and dense. There shall be no defects such as peeling, bubbles, flower spots, partial uncoated areas, scratches, etc.

噴涂應平整、光滑、均勻、不起皮、無氣泡水泡。

The spraying should be smooth, even, without peeling or bubbles.

橋架焊縫表面均勻,不得有漏焊、裂紋、夾渣、燒穿、弧坑等缺陷。

The surface of the bridge welding seam should be uniform and free of defects such as missed welding, cracks, slag inclusion, burn through, arc craters, etc.

橋架螺栓孔徑,在螺桿直徑不大于M16時,可比螺桿直徑大2mm。

The hole diameter of the bridge bolt can be 2mm larger than the screw diameter when the screw diameter is not greater than M16.

螺栓連接孔的孔距允許偏差:同一組內相鄰兩孔間距±0.7mm,同一組內任意兩孔間距±1mm;相鄰兩組的端孔間距±1.2mm。

The allowable deviation for the distance between bolt connection holes is: the distance between adjacent holes in the same group is ± 0.7mm, the distance between any two holes in the same group is ± 1mm, and the distance between end holes in adjacent groups is ± 1.2mm.

7.膨脹螺栓:應根據允許拉力和剪力進行選擇;可按計劃驗收,絲扣應完好無損。

7. Expansion bolts: should be selected based on allowable tensile and shear forces; The inspection can be carried out according to the plan, and the thread should be intact and undamaged.

8.電纜應有合格證和“CCC”認證標志,并應有“CCC”認證復印件;每盤電纜上應標明規格、型號、電壓等級、長度及出廠日期電纜相應完好無損。

8. The cable should have a certificate of conformity and the "CCC" certification mark, and should have a copy of the "CCC" certification; Each cable reel should indicate the specifications, model, voltage level, length, and date of manufacture, and the cable should be intact and undamaged accordingly.

9.電纜外觀完好無損,鎧裝無銹蝕、無機械操作,無皺折和扭曲現象。油浸電纜應密封良好,無漏油及滲油現象。橡套及塑料電纜外皮及絕緣層無老化及裂紋。電纜端頭密封良好。

9. The appearance of the cable is intact and undamaged, the armor is not corroded, there is no mechanical operation, and there is no wrinkling or twisting phenomenon. Oil immersed cables should be well sealed without oil leakage or seepage. The rubber sleeve and plastic cable sheath and insulation layer have no aging or cracks. The cable end is well sealed.

10.其它附屬材料;電纜標示牌、油漆、汽油、封鉛、硬脂酸白布帶、橡皮包布、黑包布、塑料絕緣帶等均應符合要求

10. Other ancillary materials; Cable signs, paint, gasoline, lead sealing, stearic acid white cloth tape, rubber wrap, black wrap, plastic insulation tape, etc. should all meet the requirements

3 施工工藝

3 Construction Techniques

3.1 電纜橋架安裝施工工藝

3.1 Construction process for cable tray installation

3.1.1電纜橋架安裝工藝流程:

3.1.1 Cable tray installation process:

定位放線→預埋鐵件或膨脹螺栓→支、吊、托架安裝→橋架安裝→保護接地安裝

Positioning and laying out → Pre embedded iron parts or expansion bolts → Installation of supports, hangers, and brackets → Installation of cable trays → Installation of protective grounding

3.1.2根據施工圖確定始端到終端位置,沿圖紙標定走向,找好水平、垂直、彎通,用粉線袋或畫線沿橋架走向在墻壁、頂棚、地面、梁、板、柱等處彈線或畫線,并均勻檔距畫出支、吊、托架位置。

3.1.2 Determine the starting and ending positions according to the construction drawing, mark the direction along the drawing, find the horizontal, vertical, and curved lines, use a powder line bag or draw lines along the bridge direction to snap or draw lines on walls, ceilings, floors, beams, slabs, columns, etc., and draw the positions of supports, hangers, and brackets evenly spaced.

3.1.3預埋鐵件或膨脹螺栓

3.1.3 Pre embedded iron parts or expansion bolts

(1) 預埋鐵件的自制加工不應小于120mm×80mm×6mm,做法如本標準6.3.7.2圖6.3.7.2。其錨固圓鋼的直徑不小于10mm。

(1) The self-made processing of embedded iron parts should not be less than 120mm × 80mm × 6mm, as shown in Figure 6.3.7.2 of this standard. The diameter of the anchored round steel shall not be less than 10mm.

(2) 緊密配合土建結構的施工,將預埋鐵件平面緊貼模板,將錨固圓鋼用綁扎或焊接的方法固定在結構內的鋼筋上;待混凝土模板拆除后,預埋鐵件平面外露,將支架、吊架或托架焊接在上面進行固定。

(2) Closely cooperate with the construction of civil engineering structures, tightly adhere the embedded iron parts to the formwork, and fix the anchoring round steel to the steel bars inside the structure by binding or welding; After the concrete formwork is removed, the embedded iron parts should be exposed on the surface, and the brackets, hangers or brackets should be welded on top for fixation.

(3) 根據支架承受的荷重,選擇相應的膨脹螺栓及鉆頭;埋好螺栓后,可用螺母配上相應的墊圈將支架或吊架直接固定在金屬膨脹螺栓上,可參見本標準6.3.7.7圖表。

(3) Select the corresponding expansion bolts and drill bits based on the load borne by the bracket; After burying the bolts, the bracket or hanger can be directly fixed to the metal expansion bolt with nuts and corresponding washers, as shown in Figure 6.3.7.7 of this standard.

4.支、吊架安裝

4. Installation of supports and hangers

(1) 支架與吊架所用鋼材應平直,無顯著扭曲。下料后長短偏差應在3mm范圍內,切口處應無卷邊、毛刺;

(1) The steel used for brackets and hangers should be straight and free from significant distortion. The length deviation after cutting should be within 3mm, and there should be no curled edges or burrs at the incision;

(2) 鋼支架與吊架應焊接牢固,無顯著變形,焊接前厚度超過4mm的支架、鐵件應打坡口,焊縫均勻平整,焊縫長度應符合要求,不得出現裂紋、咬邊、氣孔、凹陷、漏焊等缺陷;

(2) Steel brackets and hangers should be welded firmly without significant deformation. Brackets and iron parts with a thickness exceeding 4mm before welding should be chamfered, and the weld seam should be uniform and smooth. The weld seam length should meet the requirements and should not have defects such as cracks, undercutting, porosity, indentation, or missed welding;

(3)支架與吊架應安裝牢固,保證橫平豎直,在有坡度的建筑物上安裝支架與吊架應與建筑物的坡度、角度一致;

(3) The brackets and hangers should be installed firmly, ensuring horizontal and vertical alignment. When installing brackets and hangers on buildings with slopes, they should be consistent with the slope and angle of the building;

支架與吊架的規格一般不應小于扁鋼30mm×3mm;角鋼25mm×25mm×3mm;

The specifications of brackets and hangers should generally not be less than 30mm × 3mm for flat steel and 25mm × 25mm × 3mm for angle steel;

(5)嚴禁用電氣焊切割鋼結構或輕鋼龍骨任何部位;

(5) It is strictly prohibited to use electrical welding to cut any part of steel structures or light steel joists;

(6)吊具應采用定型產品,并應有各自獨立的吊裝卡具或支撐系統。

(6) Universal lifting devices should use standardized products and have their own independent lifting fixtures or support systems.

(7)固定支點間距一般不應大于1.5~2m。在進出接線盒、箱、柜、轉角、轉彎和變形縫兩端及丁字接頭的三端500mm以內應設固定支持點。

(7) The distance between fixed support points should generally not exceed 1.5-2m. Fixed support points should be set within 500mm at both ends of the entrance and exit junction boxes, boxes, cabinets, corners, bends, and deformation joints, as well as at the three ends of the T-shaped joint.

(8)嚴禁用木磚固定支架與吊架。

(8) It is strictly prohibited to use wooden bricks to fix brackets and hangers.

5.橋架安裝

5. Bridge installation

(1) 電纜橋架水平敷設時,支撐跨距一般為1.5~3m,電纜橋架垂直敷設時固定點間距不宜大于2m。橋架彎通彎曲半徑不大于300mm時,應在距彎曲段與直線段結合處300~600mm的直線段側設置一個支、吊架。當彎曲半徑大于300mm時,還應在彎通中部增設一個支、吊架。支、吊架和橋架安裝必須考慮電纜敷設彎曲半徑滿足規范小彎曲半徑。見表3.1.5。

(1) When laying cable trays horizontally, the support span is generally 1.5-3m. When laying cable trays vertically, the spacing between fixed points should not exceed 2m. When the bending radius of the tray is not greater than 300mm, a support or hanger should be set on the side of the straight section 300-600mm away from the junction of the curved section and the straight section. When the bending radius is greater than 300mm, a support or hanger should be added in the middle of the bend. The installation of supports, hangers, and cable trays must consider that the bending radius of cable laying meets the minimum bending radius specified in the specifications. See Table 3.1.5.

注為電纜外徑。

Note the outer diameter of the cable.

(2)門型角鋼支架的安裝:梯型橋架沿墻垂直敷設,可使用門型角鋼支架,支架的固定應盡可能配合土建施工預埋。如圖3.1.5(2-1),也可在土建施工中預埋開角螺栓,用開角螺栓固定支架如圖3.1.5(2-1),也可以采用膨脹螺栓固定。

(2) Installation of door type angle steel bracket: The ladder type bridge is vertically laid along the wall, and door type angle steel bracket can be used. The fixation of the bracket should be embedded as much as possible in conjunction with civil construction. As shown in Figure 3.1.5 (2-1), angle bolts can also be pre embedded in civil construction to fix the bracket as shown in Figure 3.1.5 (2-1), or expansion bolts can be used for fixation.

(3)梯型角鋼支架的安裝:橋架沿墻、柱水平安裝時,托壁需安裝在異型鋼立柱上,而立柱要安裝在梯型角鋼支架上,使柱和墻上的橋架固定支架(或托臂)在同一條直線上。制作見圖和表3.1.5(3)底架與門型架焊接時,焊角高度5mm。

(3) Installation of ladder type angle steel bracket: When the bridge is installed horizontally along the wall or column, the support wall needs to be installed on the special-shaped steel column, and the column needs to be installed on the ladder type angle steel bracket, so that the fixed bracket (or support arm) of the column and the bridge on the wall are in the same straight line. When welding the chassis and door frame as shown in Figure 3.1.5 (3), the welding angle height should be 5mm.

(4)電纜橋架立柱側壁式安裝:立柱是直接支承托臂的部件,分工字鋼槽鋼、角鋼、異型鋼立柱;立柱可以在墻上、柱上安裝、也可懸吊在梁板上安裝。做法在混凝土可預埋鐵件;砌體可砌筑預制砌塊;也可以采用膨脹螺栓但必須在混凝土強度C20或磚強度在MU10以上的磚砌體上,作法可參照3.1.5(4a、b、c、d、e、f)。

(4) Side wall installation of cable tray columns: The columns are components that directly support the support arms, and are divided into steel channel steel, angle steel, and special-shaped steel columns; Columns can be installed on walls, columns, or suspended from beams and slabs. The method involves embedding iron components in concrete; Prefabricated masonry blocks can be used for masonry construction; Expansion bolts can also be used, but they must be used on brick masonry with concrete strength C20 or brick strength above MU10. The method can refer to section 3.1.5 (4a, b, c, d, e, f).

(5)電纜橋架應敷設在易燃易爆氣體管和熱力管道的下方,當設計無要求時,與管道的小凈距,符合3.1.5(5)的規定。

(5) Cable trays should be laid below flammable and explosive gas pipelines and thermal pipelines. When there are no design requirements, the minimum clear distance from the pipeline should comply with the provisions of 3.1.5 (5).

6 托臂安裝:

Installation of Arm 6:

托臂是直接支承托盤、梯架單獨固定的剛性部件,托臂有螺栓固定可預埋螺栓,也可采用膨脹螺栓,也可卡接,如圖3.1.6(1)、(2)、(3)、(4)、(5)。

The support arm is a rigid component that directly supports the tray and ladder frame and is fixed separately. The support arm can be fixed with bolts that can be embedded, expansion bolts, or clamped, as shown in Figure 3.1.6 (1), (2), (3), (4), and (5).

3.2 橋架安裝

3.2 Bridge installation

1.直線段鋼制電纜橋架長度超過30m,鋁合金或玻璃鋼制電纜橋架長度超過15m應設有伸縮節,跨越伸縮縫處設置補償裝置,可用帶伸縮節的橋架。

1. If the length of a straight steel cable tray exceeds 30m, or if the length of an aluminum alloy or fiberglass cable tray exceeds 15m, expansion joints should be installed. Compensation devices should be installed at the expansion joint crossing points, and cable trays with expansion joints can be used.

2.橋架與支架間螺栓、橋架連接板螺栓緊固無遺漏,螺母位于橋架外側,當鋁合金橋架與鋼支架固定時,有相互間絕緣防電化措施腐蝕措施,一般可墊石棉墊。

2. The bolts between the bridge and the bracket, as well as the bolts of the bridge connecting plate, are tightened without omission, and the nuts are located on the outside of the bridge. When the aluminum alloy bridge and the steel bracket are fixed, there are mutual insulation and corrosion prevention measures, and asbestos pads can generally be used.

3.敷設在豎井內和穿越不同防火區的橋架,應按設計要求位置,有防火隔離措施,電纜橋架在電氣豎井內敷設可采用角鋼固定,見圖3.1.8。

3. Cable trays laid in vertical shafts and crossing different fire zones should be located according to design requirements and have fire isolation measures. Cable trays laid in electrical vertical shafts can be fixed with angle steel, as shown in Figure 3.1.8.

4.電纜橋架在穿過防火墻及防火樓板時,應采取防火隔離措施,防止火災沿線路延燃;防火隔離墻、板,應配合土建施工預留洞口,在洞口處預埋好護邊角鋼,施工時根據電纜敷設的層數和根數用L50×50×5角鋼作固定框,同時將固定柜焊在護邊角鋼上;也可以先作好框在土建施工中砌體或澆灌混凝土時安裝在墻、板中。

4. When cable trays pass through firewalls and fire-resistant floor slabs, fire-resistant isolation measures should be taken to prevent fires from spreading along the line; Fire isolation walls and panels should be equipped with reserved openings for civil construction, and edge protection angle steel should be pre embedded at the openings. During construction, L50 × 50 × 5 angle steel should be used as a fixed frame according to the number of layers and cables laid, and the fixed cabinet should be welded to the edge protection angle steel; Alternatively, the frame can be installed in the wall or slab during masonry or concrete pouring in civil construction.

3.3 橋架的接地,當設計允許利用橋架系統構成接地干線回路時,應符合下列要求:

3.3 When the design allows the use of the bridge system to form a grounding main circuit, the grounding of the bridge should meet the following requirements:

1. 金屬電纜橋架及其支架引入或引出的金屬電纜導管必須接地(PE)或接零(PEN)可靠,且必須符合下列規范:

1. Metal cable trays and their brackets must have reliable grounding (PE) or neutral (PEN) for the metal cable conduits introduced or led out, and must comply with the following specifications:

(1) 金屬電纜橋架及其支架全長,與接地(PE)或接零(PEN)干線相連接不小于2處,使整個橋架為一個電氣通路。

(1) The entire length of the metal cable tray and its support shall be connected to the grounding (PE) or neutral (PEN) main line at no less than 2 points, making the entire tray an electrical pathway.

(2) 非鍍鋅電纜橋架間連接的兩端跨接銅芯接地線,接地線小允許截面積不小于4mm2。

(2) The two ends of the non galvanized cable tray are connected with copper core grounding wires, and the minimum allowable cross-sectional area of the grounding wire is not less than 4mm2.

(3) 鍍鋅電纜橋架間連接板的兩端可不跨接接地線,但連接板兩端不少于2個有防松螺帽或防松墊圈的連接固定螺栓。

(3) The two ends of the connecting plate between galvanized cable trays may not be connected to the grounding wire, but there shall be no less than 2 fixing bolts with anti loosening nuts or anti loosening washers at both ends of the connecting plate.

2. 盤、梯架端部之間連接電阻不應大于0.00033Ω并應用等電位聯結測試儀(導通儀)或微Ω表測試,測試應在連接點的兩側進行,對整個橋架全長的兩端連接電阻不應大于0.5Ω或由設計決定,否則應增加接地點,以滿足要求。接地孔應涂層,與涂層接觸的螺栓有一側的平墊應使用帶爪的專用接地墊圈。

2. The connection resistance between the ends of the tray and ladder should not exceed 0.00033 Ω and should be tested using an equipotential bonding tester (continuity meter) or a micro Ω meter. The test should be conducted on both sides of the connection point, and the connection resistance at both ends of the entire length of the bridge should not exceed 0.5 Ω or be determined by the design. Otherwise, a grounding point should be added to meet the requirements. The grounding hole should eliminate the coating, and the flat pad on one side of the bolt in contact with the coating should use a special grounding washer with claws.

3. 伸縮縫或軟連接處需采用編織銅線連接。沿橋架全長另敷設接地干線時,每段(包括非直線段)托盤、梯架應小有一點與接地干線可靠連接;在接地部位的連接處應裝置彈簧墊圈,以免松動。

3. Expansion joints or soft connections should be connected using braided copper wires. When laying a grounding main line along the entire length of the bridge, each section (including non-linear sections) of the tray and ladder should be reliably connected to the grounding main line at a small point; A spring washer should be installed at the connection point of the grounding part to prevent loosening.

電纜橋架作為布線工程的一個配套項目,目前尚無專門的規范指導,個生產廠家的規格程式缺乏通用性,因此,設計選型過程應根據弱電各個系統纜顯得類型、數量,合理選定適用的橋架。(1)確定方向: 根據建筑平面布置圖,結合空調管線和電氣管線等設置情況、方便維修,以及電纜路由的疏密來確定電纜橋架的路由。在室內,盡可能沿建筑物的墻、柱、梁及樓板架設,如許利用綜合管廊架設時,則應在管道一側或上方平行架設,并考慮引下線和分支線盡量避免交叉,如無其它管架借用,則需自設立(支)柱。

As a supporting project of wiring engineering, there is currently no specialized specification guidance for cable trays, and the specifications and programs of individual manufacturers lack universality. Therefore, the design and selection process should be based on the type and quantity of cables in various weak current systems, and the appropriate cable tray should be selected reasonably. (1) Determine direction: Determine the optimal route for cable trays based on the building layout plan, combined with the installation of air conditioning and electrical pipelines, convenient maintenance, and the density of cable routing. Indoors, try to install along the walls, columns, beams, and floor slabs of the building as much as possible. When using a comprehensive pipe gallery for installation, parallel installation should be carried out on one side or above the pipeline, and consideration should be given to avoiding crossing of down conductors and branch lines as much as possible. If there are no other pipe racks to borrow, self installing (supporting) columns is required.

(2)荷載計算:計算電纜橋架主干線縱斷面上單位長度的電纜重量。

(2) Load calculation: Calculate the weight of cables per unit length on the longitudinal section of the main cable tray.

(3)確定橋架的寬度:根據布放電纜條數、電纜直徑及電纜的間距來確定電纜橋架的型號、規格, 托臂的長度,支柱的長度、間距,橋架的寬度和層數。

(3) Determine the width of the cable tray: Determine the model and specifications of the cable tray, the length of the support arm, the length and spacing of the pillars, the width and number of layers of the cable tray based on the number of cables laid, the diameter of the cables, and the spacing between the cables.

(4)確定安裝方式:根據場所的設置條件確定橋架的固定方式,選擇懸吊式、直立式、側壁式或是混合式,連接件和緊固件一般是配套供應的,此外,根據橋架結構選折相應的蓋板。

(4) Determine installation method: Determine the fixing method of the bridge according to the setting conditions of the site, choose suspended, upright, side wall or hybrid, and the connectors and fasteners are generally supplied together. In addition, select the corresponding cover plate according to the structure of the bridge.

(5)繪出電纜橋架平、剖面圖,局部部位還應繪出空間圖,開列材料表。

(5) Draw a plan and section diagram of the cable tray, and also draw a spatial diagram of some parts, and list the material list.

2、如與電力電纜橋架合用時,應將電力電纜和弱電電纜各直一側,中間采用隔板分隔。

2. When used in conjunction with power cable trays, the power cables and weak current cables should be placed on one side each, and separated by a partition in the middle.

3、弱電電纜與其它低電壓電纜合用橋架時,應嚴格執行選擇具有外屏蔽層的弱電系統的弱電電纜,避免相互間的干擾。

3. When weak current cables are used in cable trays with other low voltage cables, it is necessary to strictly select weak current cables with external shielding layers to avoid interference between them.

4、電纜橋架安裝要求

4. Installation requirements for cable trays

(1)槽式大跨距電纜橋架由室外進入建筑物內時,橋架向外的坡度不得小于1/100。(2)電纜橋架與用電設備交越時,其間的凈距不小于0.5m。

(1) When the trough type large-span cable tray enters the building from the outside, the outward slope of the tray shall not be less than 1/100. (2) When the cable tray intersects with electrical equipment, the clear distance between them shall not be less than 0.5m.

(3)兩組電纜橋架在同一高度平行敷設時,其間凈距不小于0.6m。(4)在平行圖上繪出橋架的路由,要注明橋架起點、終點、拐彎點、分支點及升降點的坐標或定位尺寸、標高,如能繪制橋架敷設軸側圖,則對材料統計將更精確。

(3) When two sets of cable trays are laid in parallel at the same height, the clear distance between them should not be less than 0.6m. (4) When drawing the routing of the tray on a parallel diagram, the coordinates or positioning dimensions and elevations of the starting point, ending point, turning point, branching point, and lifting point of the tray should be indicated. If a cable tray laying axis side diagram can be drawn, the material statistics will be more accurate.

直線段:注明全長、橋架層數、標高、型號及規格。拐彎點和分支點:注明所用轉彎接板的型號及規格。升降段:注明標高變化,也可用局部大樣圖或剖面圖表示。

Straight line segment: indicate the total length, number of bridge layers, elevation, model, and specifications. Turning and branching points: indicate the model and specifications of the turning joint used. Lifting section: indicate the elevation change, and it can also be represented by local detailed drawings or sectional drawings.

(5)橋架支撐點, 如立柱、托臂或非標準支、構架的間距、安裝方式、型號規格、標高,可同意在平面上列表說明,也可分段標出用不同的剖面圖、單線圖或大樣圖表示。

(5) The spacing, installation method, model specifications, and elevation of bridge support points, such as columns, brackets, or non-standard supports and structures, can be listed and explained on the plane, or segmented and marked with different sectional drawings, single line drawings, or detailed drawings.

(6)電纜引下點位置及引下方式,一般而言,大批電纜引下可用垂直彎接板和垂直引上架,少量電纜引下可用導板或引管,注明引下方式即可。

(6) Generally speaking, for a large number of cable leads, vertical bending plates and vertical lead frames can be used, while for a small number of cable leads, guide plates or guide pipes can be used, indicating the lead method.

(7)電纜橋架宜高出地面2.2米以上,橋架頂部距頂棚或其它障礙物不應小于0.3米,橋架寬度不宜小于0.1米,橋架內橫斷面的填充率不應超過50%。

(7) The cable tray should be at least 2.2 meters above the ground, and the distance between the top of the tray and the ceiling or other obstacles should not be less than 0.3 meters. The width of the tray should not be less than 0.1 meters, and the filling rate of the cross-section inside the tray should not exceed 50%.

(8)電纜橋架內纜線垂直敷設時,在纜線的上端和每間隔1.5米處應固定在橋架的支架上,水平敷設時, 在纜線的首、尾、轉彎及每間隔3~5米處進行固定。

(8) When the cables are vertically laid in the cable tray, they should be fixed on the brackets of the tray at the upper end and every 1.5 meters. When laid horizontally, they should be fixed at the beginning, end, turn, and every 3-5 meters.

(9)在吊頂內設置時,槽蓋開啟面應保持80毫米的垂直凈空,線槽截面利用率不應超過50%。

(9) When installed in the ceiling, the opening surface of the trough cover should maintain a vertical clearance of 80 millimeters, and the utilization rate of the trough section should not exceed 50%.

(10)布放在線槽的纜線可以不綁扎,槽內纜線應順直,槽內纜線應順直,盡量不交叉,纜線不應溢出線槽,在纜線進出線槽部位, 轉彎處應綁扎固定。垂直線槽布放纜線應每間隔1.5米固定在纜線支架上。

(10) The cables laid in the cable trough can be left unbound. The cables inside the trough should be straight and straight, avoiding crossing as much as possible. The cables should not overflow from the trough. They should be tied and fixed at the entrance and exit of the trough, as well as at turns. The cables laid in the vertical cable tray should be fixed on the cable support every 1.5 meters.

(11)在水平、垂直橋架和垂直線槽中敷設線時,應對纜線進行綁扎。4對線電纜以24根為束,25對或以上主干線電纜、光纜及其它信號電纜應根據纜線的類型、纜徑、纜線芯數分束綁扎。綁扎間距不宜大于1.5米,扣間距應均勻,松緊適度。

(11) When laying wires in horizontal and vertical cable trays and vertical trunking, the cables should be tied. 4-pair cables should be bundled with 24 cables, and 25 or more pairs of backbone cables, optical cables, and other signal cables should be bundled and tied according to the type, diameter, and number of cable cores. The binding spacing should not exceed 1.5 meters, the buckle spacing should be uniform, and the tightness should be moderate.

(12)橋架水平敷設時,支撐間距一般為1.5-3m,垂直敷設時固定在建筑物構體上的間距宜小于2m。

(12) When laying the bridge horizontally, the support spacing is generally 1.5-3m, and when laying vertically, the spacing fixed on the building structure should be less than 2m.

電纜橋架型式及品種的選擇及鋪設規范

Selection and laying specifications for cable tray types and varieties

一、電纜橋架型式及品種的選擇

1、 Selection of cable tray types and varieties

1、需屏蔽電氣干擾的電纜網路或有防護外部(如:有腐蝕液休,易燃粉塵等環境)影響的要求時,應選用(FB)類槽式復合型防腐屏蔽電纜橋架(帶蓋)

1. When it is required to shield cable networks from electrical interference or to protect against external influences (such as corrosive liquids, flammable dust, etc.), (FB) type slot type composite anti-corrosion shielding cable trays (with covers) should be selected

2、強腐蝕性環境應采用(F)類復合環氧樹脂防腐阻燃型電纜橋架。托臂、支架也要選用同樣材料,提高橋架及附件的使用壽命,電纜橋架。在容易積灰和其它需遮蓋的環境或戶外場所宜加蓋板。

2. For highly corrosive environments, (F) type composite epoxy resin anti-corrosion and flame-retardant cable trays should be used. The same materials should be used for the support arm and bracket to improve the service life of the cable tray and accessories. Cover plates should be added in environments or outdoor places that are prone to dust accumulation and require cover.

3、除上述情況外,可根據現場還環境及技術要求選用托盤式、槽式、梯級式、玻璃防腐阻燃電纜橋架或鋼質普通型橋架。在容易積灰和其它需遮蓋的環境或戶外場所宜加蓋板。

3. In addition to the above situations, tray type, trough type, step type, glass anti-corrosion and flame-retardant cable trays or steel ordinary cable trays can be selected according to the on-site environment and technical requirements. Cover plates should be added in environments or outdoor places that are prone to dust accumulation and require cover.

4、在公共通道或戶外跨越道路段,底層梯級的底部宜加墊板或在該段使用托盤 。大跨距跨越公共通道時,可根據用戶要求提高橋架的載荷能力或選用行架。

4. When crossing public passages or outdoor road sections, it is advisable to add padding or use pallets at the bottom of the lower steps. When crossing public passages with large spans, the load capacity of the bridge frame can be increased or a scaffolding can be selected according to user requirements.

5、大跨距(>3m)要選用復合型橋架(FB)。

5. Composite cable trays (FB) should be selected for large spans (>3m).

6、戶外要選用復合環氧樹指橋架(F)。

6. Choose composite epoxy tree finger bridge (F) for outdoor use.

二、電纜橋架規格選擇

2、 Selection of cable tray specifications

1、復合環氧樹脂電纜橋架的寬度和高度就按下表選擇,并應符合電纜真充率不超過有關標準規范的規定值,動力電纜可取40-50%,控制電纜可取50-70%,另外需予留10-25%的式程發展余量。

1. The width and height of the composite epoxy resin cable tray should be selected according to the table below, and should comply with the specified values of the cable true filling rate not exceeding the relevant standard specifications. The power cable can be taken as 40-50%, the control cable can be taken as 50-70%, and an additional 10-25% formula development margin should be reserved.

2、各種彎通及附件規格應符合工程布置條件并與橋架相配套。

2. The specifications of various bends and accessories should comply with the engineering layout conditions and be compatible with the bridge frame.

3、支、吊架規格的選擇,應按橋架規格、層數、跨距等條件配置。并應滿足荷載的要求。

3. The selection of support and hanger specifications should be configured according to the specifications, number of layers, span, and other conditions of the bridge frame. And it should meet the requirements of the load.

4、橋架橫截面積的選擇見表橋架上電纜網絡中任一線路的自動過電流保護的額定電流值或整定值(A) 橋架橫截面充許小值(mm2)0-60 12961-100 258101-200 452201-400 645401-600 968

4. The selection of the cross-sectional area of the cable tray is shown in the table. The rated current value or setting value of the maximum automatic overcurrent protection for any line in the cable network on the cable tray (A). The minimum allowable cross-sectional area of the cable tray (mm2) is 0-60 12961-100 258101-200 452201-400 645401-600 968

三、對于電纜橋架的支、吊架的配置

3、 Configuration of supports and hangers for cable trays

1、戶內支、吊短跨距一般采取1.5-3m。戶外立柱中跨距一般采取6m。

1. The short span of indoor supports and hangers is generally 1.5-3m. The mid span of outdoor columns is generally 6m.

2、非直線段的支、吊架配置就遵循以下原則。當橋架寬度<300mm時,應在距非直線段與直線結合處300-600m的直線段側設置一個支、吊架。當橋架寬度>300mm時,除符合下述條件外,在非直線段中部還應增設一個支、吊架。

2. The configuration of supports and hangers for non-linear sections follows the following principles. When the width of the bridge is less than 300mm, a support and hanger should be installed on the side of the straight section 300-600m away from the junction of the non-linear section and the straight section. When the width of the bridge is greater than 300mm, in addition to meeting the following conditions, a support or hanger should be added in the middle of the non-linear section.

3、拉擠玻璃鋼電纜橋架多層設置時層間中心距為200,250,300,350mm。

3. When setting up multiple layers of extruded fiberglass cable trays, the center distance between layers is 200250300350mm.

4、橋架直線段每隔50m應予留伸縮縫20-30mm(金屬橋架)。

4. Expansion joints of 20-30mm (metal bridge) should be left every 50m in the straight section of the bridge.

四、防火:要求橋架防火的區段,必須采用鋼制或不燃、阻燃材料。

4、 Fire prevention: Steel or non combustible and flame-retardant materials must be used in the sections where bridge frames are required to be fire-resistant.

五、拉擠玻璃鋼電纜橋架的接地

5、 Grounding of extruded fiberglass cable tray

1、橋架系統應具有可靠的電氣連接并接地(只對金屬橋架)。

1. The cable tray system should have reliable electrical connections and grounding (only for metal cable trays).

2、當允許利用橋架系統構成接地干線回路時應符合下列要求。橋架端部之間連接電阻應不大于0.00033歐姆,接地孔應絕緣涂層。在1KV及以下中性點直接接地系統中,受電設備的接地與系統中性線接地相連。裝有處動切斷供電裝軒時,橋架的級長方向金屬橫截面積應不小于規定值。

2. When it is allowed to use a bridge system to form a grounding main circuit, the following requirements should be met. The connection resistance between the ends of the bridge should not exceed 0.00033 ohms, and the insulation coating should be removed from the grounding hole. In a neutral point direct grounding system of 1KV and below, the grounding of the receiving equipment is connected to the neutral line grounding of the system. When installing a power cut-off device, the cross-sectional area of the metal in the longitudinal direction of the bridge should not be less than the specified value.

3、沿橋架全長另敷設接地干線時,每段(包括非直線段)橋架應少有一點與接地干線可靠連接。

3. When laying a grounding main line along the entire length of the bridge, each section (including non-linear sections) of the bridge should have at least one point reliably connected to the grounding main line.

4、對于振動場所,在接地部位的連接處應裝置彈簧圈。

4. For vibration sites, spring coils should be installed at the connection of the grounding point.

六、橋架系統設計內容:橋架系統工程設計應與土建、工藝以及有關密切相配合以確定布置,其設計內容可含有:

6、 Bridge system design content: The bridge system engineering design should be closely coordinated with civil engineering, technology, and related disciplines to determine the optimal layout. Its design content may include:

1、橋架系統的有關剖面圖。2、橋架系統的平面布置圖。3、橋架系統所需直線段、彎通、支、吊架規格和數量的明細表以及必要的說明。4、有特殊要求的非標件技術說明或示意圖。

1. Relevant sectional drawings of the bridge system. 2. Layout plan of the bridge system. 3. A detailed list of specifications and quantities of straight sections, bends, supports, and hangers required for the bridge system, along with necessary explanations. 4. Technical specifications or diagrams for non-standard parts with special requirements.

七、安裝:電纜橋架的安半夜請參照建筑標準設計研究院所發行的JSJT-121全國通用建筑標準設計-電氣裝置標準圖集《電纜橋架安裝》。

7、 Installation: For the installation of cable trays, please refer to the JSJT-121 National General Building Standard Design Electrical Equipment Standard Atlas "Cable Tray Installation" issued by the China Building Standards Design and Research Institute.

八、設計要求

8、 Design requirements

1、橋架系統的路徑平面布置圖;

1. Layout plan of the cable tray system path;

2、橋架系統的有關斷面圖。

2. The relevant cross-sectional diagram of the bridge system.

3、橋架系統所用防腐材質及所需直通、彎通、支(吊)架等的規格和數量明細表以及必要的說明,連接板及螺絲、防護帽按以上要求由生產廠家配齊。4、有特殊要求的非標準技術說明或示圖。

3. The anti-corrosion materials used in the bridge system, as well as the specifications and quantities of the required straight through, bent through, support (suspension) frames, and necessary explanations, shall be detailed. The connecting plates, screws, and protective caps shall be provided by the manufacturer in accordance with the above requirements. 4. Non standard technical specifications or diagrams with special requirements.

一、電纜橋架型式及品種的選擇

1、 Selection of cable tray types and varieties

1、需屏蔽電氣干擾的電纜網路或有防護外部(如:有腐蝕液休,易燃粉塵等環境)影響的要求時,應選用(FB)類槽式復合型防腐屏蔽電纜橋架(帶蓋) 2、強腐蝕性環境應采用(F)類復合環氧樹脂防腐阻燃型電纜橋架。托臂、支架也要選用同樣材料,提高橋架及附件的使用壽命,電纜橋架。在容易積灰和其它需遮蓋的環境或戶外場所宜加蓋板。 3、除上述情況外,可根據現場還環境及技術要求選用托盤式、槽式、梯級式、玻璃防腐阻燃電纜橋架或鋼質普通型橋架。在容易積灰和其它需遮蓋的環境或戶外場所宜加蓋板。 4、在公共通道或戶外跨越道路段,底層梯級的底部宜加墊板或在該段使用托盤 。大跨距跨越公共通道時,可根據用戶要求提高橋架的載荷能力或選用行架。 5、大跨距(>3m)要選用復合型橋架(FB)。

1. When it is required to shield cable networks from electrical interference or to protect against external influences (such as corrosive liquids, flammable dust, etc.), (FB) type slot type composite anti-corrosion shielding cable trays (with covers) should be selected. 2. For highly corrosive environments, (F) type composite epoxy resin anti-corrosion and flame-retardant cable trays should be used. The same materials should be used for the support arm and bracket to improve the service life of the cable tray and accessories. Cover plates should be added in environments or outdoor places that are prone to dust accumulation and require cover. 3. In addition to the above situations, tray type, trough type, step type, glass anti-corrosion and flame-retardant cable trays or steel ordinary cable trays can be selected according to the on-site environment and technical requirements. Cover plates should be added in environments or outdoor places that are prone to dust accumulation and require cover. 4. When crossing public passages or outdoor road sections, it is advisable to add padding or use pallets at the bottom of the lower steps. When crossing public passages with large spans, the load capacity of the bridge frame can be increased or a scaffolding can be selected according to user requirements. 5. Composite cable trays (FB) should be selected for large spans (>3m).

6、戶外要選用復合環氧樹指橋架(F)。

6. Choose composite epoxy tree finger bridge (F) for outdoor use.

二、規格選擇

2、 Specification selection

1、橋架的寬度和高度就按下表選擇,并應符合電纜真充率不超過有關標準規范的規定值,動力電纜可取40-50%,控制電纜可取50-70%,另外需予留10-25%的式程發展余量。 2、各種彎通及附件規格應符合工程布置條件并與橋架相配套。 3、支、吊架規格的選擇,應按橋架規格、層數、跨距等條件配置。并應滿足荷載的要求。 4、橋架橫截面積的選擇見表 橋架上電纜網絡中任一線路的自動過電流保護的額定電流值或整定值(A) 橋架橫截面充許小值(mm2) 0-60 129 61-100 258 101-200 452 201-400 645 401-600 968

1. The width and height of the cable tray should be selected according to the table below, and should comply with the specified values of the cable true filling rate not exceeding the relevant standard specifications. The power cable can be taken as 40-50%, the control cable can be taken as 50-70%, and an additional 10-25% of the formula development margin should be reserved. 2. The specifications of various bends and accessories should comply with the engineering layout conditions and be compatible with the bridge frame. 3. The selection of support and hanger specifications should be configured according to the specifications, number of layers, span, and other conditions of the bridge frame. And it should meet the requirements of the load. 4. The selection of the cross-sectional area of the cable tray is shown in the table. The rated current value or setting value of the maximum automatic overcurrent protection for any line in the cable network on the tray (A). The minimum allowable cross-sectional area of the tray (mm2) is 0-60 129 61-100 258 101-200 452 201-400 645 401-600 968

三、支、吊架的配置

3、 Configuration of supports and hangers

1、戶內支、吊短跨距一般采取1.5-3m。戶外立柱中跨距一般采取6m。

1. The short span of indoor supports and hangers is generally 1.5-3m. The mid span of outdoor columns is generally 6m.

2、非直線段的支、吊架配置就遵循以下原則。當橋架寬度<300mm時,應在距非直線段與直線結合處300-600m的直線段側設置一個支、吊架。當橋架寬度>300mm時,除符合下述條件外,在非直線段中部還應增設一個支、吊架。

2. The configuration of supports and hangers for non-linear sections follows the following principles. When the width of the bridge is less than 300mm, a support and hanger should be installed on the side of the straight section 300-600m away from the junction of the non-linear section and the straight section. When the width of the bridge is greater than 300mm, in addition to meeting the following conditions, a support or hanger should be added in the middle of the non-linear section.

3、橋架多層設置時層間中心距為200,250,300,350mm。

3. When setting up multiple layers of cable trays, the center distance between layers is 200250300350mm.

4、橋架直線段每隔50m應予留伸縮縫20-30mm(金屬橋架)。

4. Expansion joints of 20-30mm (metal bridge) should be left every 50m in the straight section of the bridge.

四、防火

4、 Fire prevention

要求橋架防火的區段,必須采用鋼制或不燃、阻燃材料。我公司生產的BJⅢ系列電纜橋架均為防火橋架。

The section requiring bridge fire prevention must be made of steel or non combustible and flame-retardant materials. The BJ III series cable trays produced by our company are all fire-resistant trays.

五、接地

5、 Grounding

1、橋架系統應具有可靠的電氣連接并接地(只對金屬橋架)。

1. The cable tray system should have reliable electrical connections and grounding (only for metal cable trays).

2、當允許利用橋架系統構成接地干線回路時應符合下列要求。橋架端部之間連接電阻應不大于0.00033歐姆,接地孔應絕緣涂層。在1KV及以下中性點直接接地系統中,受電設備的接地與系統中性線接地相連。裝有處動切斷供電裝軒時,橋架的級長方向金屬橫截面積應不小于規定值。

2. When it is allowed to use a bridge system to form a grounding main circuit, the following requirements should be met. The connection resistance between the ends of the bridge should not exceed 0.00033 ohms, and the insulation coating should be removed from the grounding hole. In a neutral point direct grounding system of 1KV and below, the grounding of the receiving equipment is connected to the neutral line grounding of the system. When installing a power cut-off device, the cross-sectional area of the metal in the longitudinal direction of the bridge should not be less than the specified value.

3、沿橋架全長另敷設接地干線時,每段(包括非直線段)橋架應少有一點與接地干線可靠連接。

3. When laying a grounding main line along the entire length of the bridge, each section (including non-linear sections) of the bridge should have at least one point reliably connected to the grounding main line.

4、對于振動場所,在接地部位的連接處應裝置彈簧圈。

4. For vibration sites, spring coils should be installed at the connection of the grounding point.

六、橋架系統設計內容

6、 Design content of bridge system

橋架系統工程設計應與土建、工藝以及有關密切相配合以確定布置,其設計內容可含有:

The design of bridge system engineering should be closely coordinated with civil engineering, technology, and relevant disciplines to determine the optimal layout, and its design content may include:

1、橋架系統的有關剖面圖。

1. Relevant sectional drawings of the bridge system.

2、橋架系統的平面布置圖。

2. Layout plan of the bridge system.

3、橋架系統所需直線段、彎通、支、吊架規格和數量的明細表以及必要的說明。

3. A detailed list of specifications and quantities of straight sections, bends, supports, and hangers required for the bridge system, along with necessary explanations.

4、有特殊要求的非標件技術說明或示意圖。

4. Technical specifications or diagrams for non-standard parts with special requirements.

七、安裝

7、 Installation

電纜橋架的安半夜請參照建筑標準設計研究院所發行的JSJT-121全國通用建筑標準設計-電氣裝置標準圖集《電纜橋架安裝》04D701-3。

For the installation of cable trays, please refer to the JSJT-121 National General Building Standard Design Electrical Equipment Standard Atlas "Cable Tray Installation" 04D701-3 issued by the China Building Standards Design and Research Institute.

八、設計要求

8、 Design requirements

1、橋架系統的路徑平面布置圖;

1. Layout plan of the cable tray system path;

2、橋架系統的有關斷面圖。

2. The relevant cross-sectional diagram of the bridge system.

3、橋架系統所用防腐材質及所需直通、彎通、支(吊)架等的規格和數量明細表以及必要的說明,連接板及螺絲、防護帽按以上要求由生產廠家配齊。

3. The anti-corrosion materials used in the bridge system, as well as the specifications and quantities of the required straight through, bent through, support (suspension) frames, and necessary explanations, shall be detailed. The connecting plates, screws, and protective caps shall be provided by the manufacturer in accordance with the above requirements.

4、有特殊要求的非標準技術說明或示圖。

4. Non standard technical specifications or diagrams with special requirements.

本文由 濟南電纜橋架 友情奉獻.更多有關的知識請點擊 http://www.zkhtkj.cn/ 真誠的態度.為您提供為的服務.更多有關的知識我們將會陸續向大家奉獻.敬請期待.

This article is a friendly contribution from Jinan Cable Bridge For more related knowledge, please click http://www.zkhtkj.cn/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

下一篇:山東電纜橋架安裝施工要求及規范

相關文章 / Recommended news

- 濟南廠房福音!大跨距橋架破解3大痛點,加強筋加,安裝省一半錢

- 山東工程人警惕!橋架敷線踩這坑必返工,監理當場叫停,國標早有明確規定

- 濟南人避坑!橋架≠線槽,90%工程人都搞混,一字之差差千里

- 避坑指南!山東電纜橋架規格別瞎選,偏大浪費偏小隱患大,國標早就定好了

- 濟南人必看!鋁合金電纜橋架選對厚度,耐用又省心,90%的人選錯踩坑

- 山東人必看!電纜橋架不是“鐵架子”,藏著建筑用電的密碼,90%的人都不懂

- 800kg/m抗壓!濟南電纜橋架,破解3大工程痛點,工期省30%

- 3種類型+98%散熱!山東電纜橋架,選對不踩坑,布線效率翻倍

- 2類核心支架!濟南電纜橋架,抗震承重雙達標

- 別再混淆!山東電纜橋架vs線槽,6大核心區別一文分清

陽極氧化鋁合金橋架

陽極氧化鋁合金橋架 托盤式電纜橋架

托盤式電纜橋架 梯式電纜橋架

梯式電纜橋架 梯式不銹鋼電纜橋架

梯式不銹鋼電纜橋架 深灰色金屬防火電纜橋架

深灰色金屬防火電纜橋架